From the design of a prototype to its mass production; From single parts to series of 5,000 units per year, ISODE offers a complete range of flexible insulation solutions up to 1370°C

Tailor made solutions

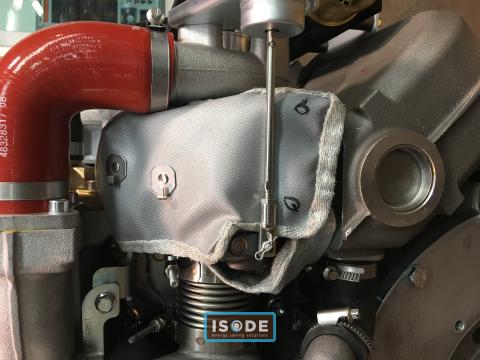

Like a second skin, our thermal and acoustic insulation jackets are tailor-made to fit the most complex shapes of your equipment, and thus limit any risk of thermal bridging and temperature passage, by limiting conduction, convection and heat radiation.

Flexible and thin, they adapt perfectly to their specific configurations, in order to confine heat flows and significantly reduce your energy consumption; moreover, they are easily removable.

Thanks to its specific sewing techniques and its multiple combinations of materials, ISODE protects your equipment against extreme temperatures and this within a low budget.

It all starts with a study of your needs; a thermal calculation, allowing, depending on the constraints of the application, to define the best type of materials (or combination of materials) to use, as well as the thicknesses necessary to fulfill the expected function.

Our in-depth knowledge of insulating materials and our know-how allow us to guarantee complete responses to the various problems exposed.

A wide range of insulators and encapsulation fabrics

Depending on your specifications, we offer a wide range of insulators and encapsulation fabrics. These certified, high performance materials meet all situations (extreme temperatures, vibrations, need for sealing, resistance to fluids, etc.). In order to facilitate assembly, different types of fasteners are possible.

Typical applications

- Pipe insulation, exhaust manifolds, catalysts, SCR, particulate filters, turbos, compressors EGR valves, NOx sensors, Scrubber

- Engine insulation for Solas certification

- Stage V / Euro 6 engine insulation

- Thermal blanket

- Soundproofing